Sheet Metal Cutting in Querétaro: 6 kW Laser Technology for Precision Cutting with FOMAI

Sheet metal cutting is a key process in industrial manufacturing, as it defines the precision, quality, and functionality of metal parts. For industries that require tight tolerances and complex geometries, having advanced technology makes a significant difference. In Querétaro, one of the country’s main industrial hubs, sheet metal cutting services in Querétaro using laser technology have become a strategic solution for high-precision projects.

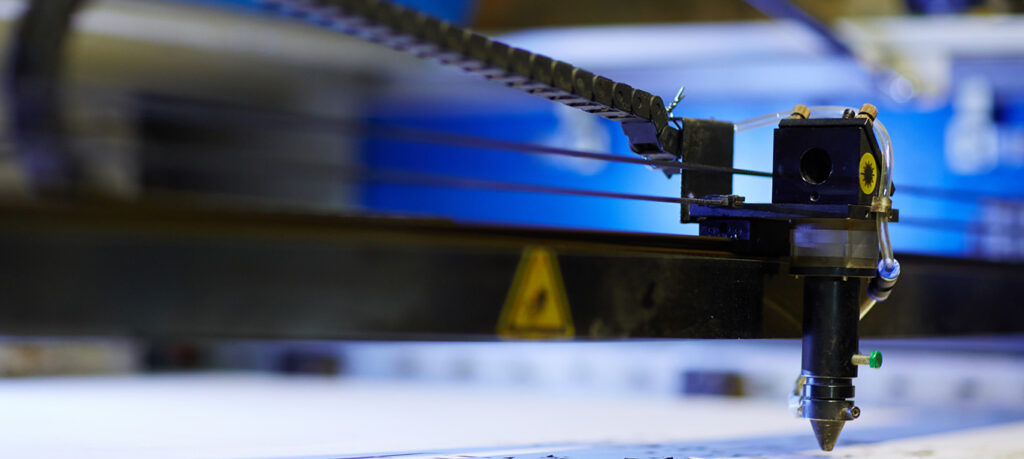

At FOMAI, we offer 6 kW laser cutting, a technology that enables the production of custom parts with clean, repeatable, and highly precise cuts, optimizing production times and reducing rework.

6 kW Laser Technology: Precision and Efficiency

High-power laser cutting allows processing different materials and thicknesses with excellent edge quality and minimal thermal distortion. Thanks to CNC control, this process ensures repeatability, dimensional accuracy, and superior finishing even for complex designs.

Our 6 kW laser cutting machine features a working area of 3,080 x 1,530 mm, enabling the processing of large-format sheets and optimizing material utilization in industrial projects.

Cutting Thickness by Material

The equipment’s capacity allows us to work with a wide range of metals commonly used in industry:

- Brass: 1 to 12 mm

- Aluminum: 1 to 16 mm

- Stainless steel: 1 to 12 mm

- Carbon steel: 1 to 22 mm

These capabilities make it possible to manufacture everything from thin, high-precision parts to thicker structural components while maintaining uniform cuts and controlled tolerances.

Industrial Applications of Laser Cutting

The sheet metal cutting service in Querétaro offered by FOMAI is designed for the production of specific parts that require accuracy from the very first process. Laser cutting is ideal for manufacturing structural components, metal reinforcements, brackets, trays, enclosures, plates, assembly parts, and custom elements for industrial machinery. This process is widely used in sectors such as construction, electrical, automotive, elevator systems, and industrial manufacturing, where cutting precision directly impacts final assembly quality.

Advantages of Laser Cutting for Industrial Parts

Laser cutting helps eliminate secondary operations, reduce material waste, and improve delivery times. In addition, as a highly controlled process, it delivers excellent repeatability in both short runs and large production batches, making it ideal for industrial projects that demand consistency and reliability. When combined with downstream processes such as punching, bending, welding, and assembly, laser cutting becomes the foundation for complete and efficient manufacturing solutions.