Stamping Services in Querétaro: Precision and Efficient Metal Part Manufacturing

Stamping is one of the most efficient processes in metal-mechanical manufacturing, especially when producing metal parts with defined shapes, high repeatability, and optimized costs. In a competitive industrial environment like Querétaro, having a specialized provider of stamping services in Querétaro allows companies to ensure quality, precision, and reliable delivery times.

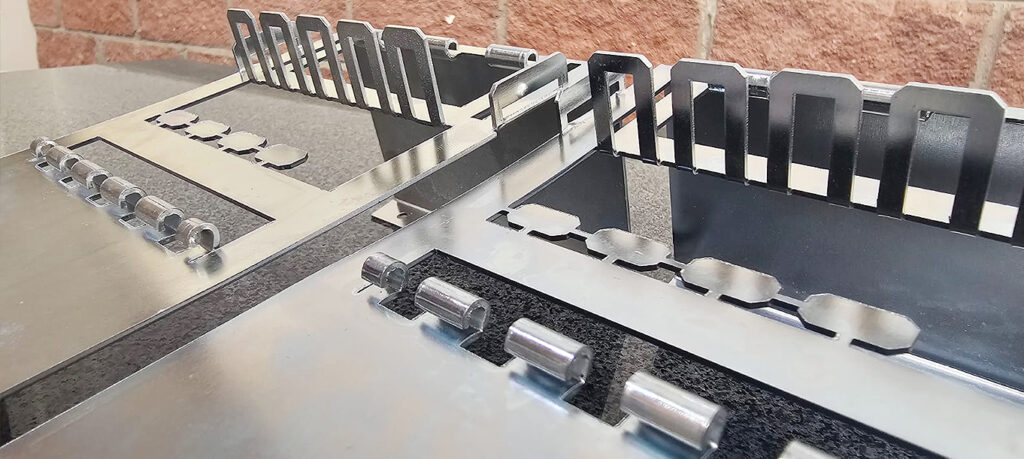

At FOMAI, we offer pneumatic CNC stamping services designed to support industrial projects that demand dimensional accuracy and efficient production.

What Is Industrial Stamping?

Stamping is a process in which sheet metal is formed using a die that cuts, pierces, or shapes the material through controlled pressure. Thanks to automation and numerical control, this process enables the continuous production of identical parts, reducing variation and ensuring uniformity in every batch.

Types of Stamping Used in Industry

The stamping service in Querétaro offered by FOMAI adapts to different design requirements and production volumes. Simple stamping is used for basic operations such as single cuts or perforations, making it ideal for low-complexity functional parts. Precision stamping allows for tighter tolerances and well-defined geometries, ensuring compatibility in industrial assemblies.

Progressive stamping, in turn, is one of the most efficient methods for mass production, as it performs multiple operations in a single pass of the sheet metal, increasing manufacturing speed and reducing cost per part.

Benefits of CNC Stamping

Automated stamping provides high repeatability, ensuring consistent parts even in large volumes. It also allows for better material utilization, reduces waste, and eliminates the need for additional manual processes. This results in faster manufacturing, controlled costs, and a lower risk of rework. Compatibility with different thicknesses and materials makes stamping a versatile solution for multiple industrial applications.

Industries Served

Stamping is widely used in industries such as automotive, electrical, construction, elevator systems, and industrial manufacturing. Stamped parts are used in metal enclosures, hardware, brackets, plates, assembly components, and metal structures that require precision and strength. Thanks to its efficiency, stamping is ideal for projects where quality and production speed are critical factors.

Quality Standards in Stamping

To ensure reliable results, industrial stamping processes must meet strict quality controls. At FOMAI, each project includes dimensional verification, lot inspection, and material traceability to ensure parts meet customer technical specifications. These processes are supported by management systems aligned with international quality standards and continuous improvement practices.